It makes a difference which ignition coil you install. Which ignition coil to choose

For more than half a century of the evolution of carburetor gasoline engines with a contact ignition system, the coil (or, as drivers of past years often called it, “reel”) has practically not changed its design and appearance, representing a high-voltage transformer in a sealed metal cup filled with transformer oil to improve the insulation between turns of windings and cooling.

An integral partner of the coil was a distributor - a mechanical low-voltage switch and a high-voltage distributor. A spark had to appear in the corresponding cylinders at the end of the compression stroke of the air-fuel mixture - strictly at a certain moment. The distributor carried out the generation of the spark, its synchronization with the engine cycles, and its distribution among the spark plugs.

The classic oil-filled ignition coil - "bobbin" (which means "coil" in French) - was extremely reliable. It was protected from mechanical influences by the steel shell of the housing, and from overheating by effective heat removal through the oil filling the glass. However, according to the poorly censored rhyme in the original version, “It wasn’t the bobbin – the idiot was sitting in the cab...”, it turns out that the reliable bobbin did sometimes fail, even if the driver is not such an idiot...

If you look at the diagram of the contact ignition system, you will find that the stopped engine could stop in any position of the crankshaft, both with the contacts of the low voltage breaker in the distributor closed and with the contacts open. If, during the previous shutdown, the engine stopped in the crankshaft position in which the distributor cam closed the contacts of the breaker supplying low voltage to the primary winding of the ignition coil, then when the driver for some reason turned on the ignition without starting the engine and left the key in this position for a long time, the primary winding of the coil could overheat and burn out... Because a direct current of 8-10 amperes began to pass through it instead of an intermittent pulse.

Officially, the coil of the classic oil-filled type cannot be repaired: after the winding burned out, it was sent for scrap. However, once upon a time, electricians at car depots managed to repair bobbins - they flared the body, drained the oil, rewound the windings and reassembled them... Yes, there were times!

And only after the mass introduction of contactless ignition, in which the distributor contacts were replaced by electronic switches, the problem of coil combustion almost disappeared. Most switches provided for automatic shutdown of the current through the ignition coil when the ignition was on but the engine was not running. In other words, after turning on the ignition, a short time interval began counting, and if the driver did not start the engine during this time, the switch automatically turned off, protecting both the coil and itself from overheating.

Dry coils

The next stage in the development of the classic ignition coil was the abandonment of the oil-filled housing. “Wet” coils were replaced by “dry” ones. Structurally, it was almost the same reel, but without a metal body and oil, coated on top with a layer of epoxy compound to protect it from dust and moisture. It worked in conjunction with the same distributor, and often on sale you could find both old “wet” coils and new “dry” ones for the same car model. They were completely interchangeable, even the “ears” of the mounts matched.

For the average car owner, there were essentially no advantages or disadvantages in changing technology from “wet” to “dry”. If the latter, of course, was made with high quality. Only manufacturers received the “profit”, since making a “dry” coil was somewhat simpler and cheaper. However, if the “dry” coils of foreign car manufacturers were initially thought out and manufactured quite carefully and served almost as long as the “wet” ones, Soviet and Russian “dry” bobbins gained notoriety because they had a lot of quality problems and failed quite often without any reason.

One way or another, today “wet” ignition coils have completely given way to “dry” ones, and the quality of the latter, even when produced domestically, is practically beyond criticism.

There were also hybrid coils: a regular “dry” coil and a regular contactless ignition switch were sometimes combined into a single module. Such designs were found, for example, on mono-injection Fords, Audis and a number of others. On the one hand, it looked somewhat technologically advanced, on the other hand, reliability decreased and the price increased. After all, two fairly heated units were combined into one, whereas separately they were cooled better, and if one or the other failed, replacement was cheaper...

Oh yes, to add to the collection of specific hybrids: on old Toyotas there was often a version of a coil integrated directly into the distributor distributor! It was, of course, not tightly integrated, and if the “bobbin” failed, it could be easily removed and purchased separately.

Ignition module - dispenser failure

A noticeable evolution in the reel world occurred during the development of injection engines. The first injectors included a “partial distributor” - the low-voltage coil circuit was already switched by the electronic engine control unit, but the spark was still distributed through the cylinders by a classic runner distributor driven by the camshaft. It became possible to completely abandon this mechanical unit by using a combined coil, in the common body of which individual coils were hidden in an amount corresponding to the number of cylinders. Such units began to be called “ignition modules.”

The electronic engine control unit (ECU) contained 4 transistor switches, which alternately supplied 12 volts to the primary windings of all four coils of the ignition module, and they, in turn, sent a high-voltage spark pulse to each of its spark plugs. Simplified versions of combined coils are even more common, more technologically advanced and cheaper to produce. In them, in one housing of the ignition module of a four-cylinder engine, not four coils are placed, but two, but they nevertheless work for four spark plugs. In this scheme, the spark is supplied to the spark plugs in pairs - that is, to one spark plug of the pair it arrives at the moment necessary to ignite the mixture, and to the other spark is idle, at the moment the exhaust gases are released from this cylinder.

The next stage in the development of combined coils was the transfer of electronic switches (transistors) from the engine control unit to the ignition module housing. Removing powerful transistors that heat up during operation “in the wild” improved the temperature regime of the ECU, and if any electronic switch switch failed, it was enough to replace the coil, rather than changing or soldering a complex and expensive control unit. In which individual immobilizer passwords and similar information are often written down for each car.

Each cylinder has a coil!

Another ignition solution typical of modern gasoline cars, which exists in parallel with modular coils, is individual coils for each cylinder, which are installed in the spark plug well and contact the spark plug directly, without a high-voltage wire.

The first “personal coils” were just coils, but then switching electronics moved into them - just as happened with ignition modules. One of the advantages of this form factor is the elimination of high-voltage wires, as well as the ability to replace only one coil, and not the whole module, if it fails.

True, it is worth saying that in this format (coils without high-voltage wires, mounted on a spark plug) there are also coils in the form of a single block, united by a common base. Such people, for example, like to use GM and PSA. This is a truly terrible technical solution: the coils seem to be separate, but if one “reel” fails, you have to replace the entire large and very expensive unit...

What have we come to?

The classic oil-filled bobbin was one of the most reliable and indestructible components in carburetor and early injection cars. Its sudden failure was considered rare. True, its reliability, unfortunately, was “compensated” by its integral partner - the distributor, and later - the electronic switch (the latter, however, applied only to domestic products). The “dry” coils that replaced the “oil” ones were comparable in reliability, but they still failed somewhat more often for no apparent reason.

Injection evolution forced us to get rid of the distributor. This is how various designs appeared that did not require a mechanical high-voltage distributor - modules and individual coils according to the number of cylinders. The reliability of such structures has further decreased due to the complication and miniaturization of their “offal”, as well as the extremely difficult conditions of their operation. After several years of operation with constant heating from the engine on which the coils were mounted, cracks formed in the protective layer of the compound, through which moisture and oil entered the high-voltage winding, causing breakdowns inside the windings and misfires. For individual coils that are installed in spark plug wells, the working conditions are even more hellish. Also, delicate modern coils do not like washing the engine compartment and the increased gap in the electrodes of the spark plugs, which is formed as a result of long-term operation of the latter. The spark always looks for the shortest path, and often finds it inside the bobbin winding.

As a result, today the most reliable and correct design that exists and is used can be called an ignition module with built-in switching electronics, installed on the engine with an air gap and connected to the spark plugs with high-voltage wires. Separate coils installed in the spark plug wells of the block head are less reliable, and, from my point of view, the solution in the form of combined coils on a single ramp is completely unsuccessful.

The ignition system of a gasoline automobile engine is designed to ignite the air-fuel mixture in the engine cylinders. For this purpose, the property of high voltage is used to create an electrical breakdown of the air gap of the spark plug. Since the on-board voltage of the car is in the vast majority of cases 12 V, ignition coils have been developed to generate high-voltage pulses. All of them, without exception, work on the same principle, but which ignition coil to choose for a particular type of engine depends on several factors.

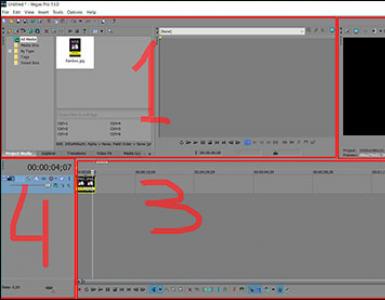

Ignition coil device

The high-voltage transformer, known among car enthusiasts as an ignition coil, is made in a classic way - two windings (high-voltage and low-voltage) and a metal core made of special transformer steel.

The reliability of the ignition coil directly depends on the quality of the windings, since the low-voltage coil operates at high current values, while the high-voltage coil is susceptible to voltage breakdowns between its own turns. To avoid interturn breakdowns and damage to wire insulation due to vibration, the windings of the coils are impregnated with special compounds.

Types of ignition coils

Historically, automobile engines were equipped with one ignition coil, and the supply of voltage to the required spark plug was organized using a contact-distribution method. This design revealed many shortcomings and was soon replaced by a more complex one, when several coils were placed in one housing, each of which was responsible for generating high voltage for two spark plugs at once. Nowadays, most new powerplants have individual ignition coils for each cylinder and are mounted directly on the spark plug.

On the one hand, the cost of the ignition system has increased, since instead of one coil, several are installed on the engine at once. On the other hand, there is no need for long high-voltage wires and the reliability of the system as a whole increases, since the failure of one coil leads to the failure of only one cylinder, and not two or all at once.

Which ignition coil to choose for a car

Most automakers develop their ignition coils in relation to a specific model of power plant. As a rule, coils are not interchangeable in terms of design and electrical characteristics. Installing the wrong coil may result in the following:

- lack of a normal spark on the spark plug;

- failure of the coil control circuit;

- failure of the coil itself.

Including the ignition coil? Use the electronic search system by car make or VIN code. The search result can be an original spare part or its full analogue from a third-party manufacturer. Don't bother going to the store, you can order and receive it in the most convenient way!

An automotive ignition coil is a small piece of metal that is used to ignite the fuel plug in engines. The lifespan of the coils is relatively short, since they have to operate at high voltages and in particularly aggressive conditions.

What are ignition coils for?

In gasoline and gas engines, the fuel mixture must be ignited. Electrical devices such as spark plugs perform the task of ignition best. However, the operating voltage in them reaches several tens of thousands of volts. This is where the coil is needed, since it can turn 12 volts of current from the battery into even 50 thousand volts. At the same time, the coil, despite its apparent simplicity, seriously suffers from external influences. For this reason, it is changed on average every 70 thousand kilometers.

More about the device

Many electrical devices are based on the use of the law of self-induction. The notorious ignition coil consists of the following elements:

- The outer layer, aka primary winding, made of thick copper wire with a diameter of 0.8 millimeters. Number of turns: 250-400 pieces;

- Inner layer, aka secondary winding, from thin copper wire with a diameter of 0.1 mm. Number of turns: 19-25 thousand pieces;

- The core is made of special transformer steel, which is an excellent affordable ferromagnet.

Also, switching devices are separately distinguished, that is, high and low voltage terminals. The second ones are connected to the battery and the metal part of the car, almost always the frame.

It works like this: the current from the selected source (in a car this is a generator or battery) initially acts in the primary winding, creating electromagnetic field. When the circuit is opened, a self-induction effect is observed: in the secondary winding, when the current strength changes (i.e., it decreases to zero), an electromotive force pulse is induced. In non-scientific terms, the secondary winding “resists” a sudden change in current in the primary winding. In this case, the magnitude of the EMF depends on the number of turns and the density of their winding. As a result, from a few volts you can get tens of thousands of volts, which are required by the ignition system.

Core make it layered - this way it heats up less. A heated core introduces excessive nonlinearity into the system, and as a result it is impossible to achieve a consistently high inductance value of the entire coil. If you get rid of the core, the inductance will be too low.

In order to avoid troubles, the coil is equipped additional resistances(avoids overheating) and capacitors (soften voltage surges, preventing the formation of sparks), isolate each layer(prevents the circuit from closing). Note that the coil partly compensates for the shortcomings of high-voltage wires.

Types of ignition systems

Depending on how the fuel mixture is ignited, the following systems are distinguished:

- Distribution. One coil took on all the work of handling multiple cylinders. The system is outdated and not very reliable, today it is found only in older cars;

- "Double Spark". High voltage from one coil powers two spark plugs, which work with synchronously moving pistons. In this case, the energy provides a spark in one candle, and is wasted in the other. There are DIS systems and a slightly modernized DIS-COP;

- Individual. The coil is installed directly onto the spark plug. There is also no need for high-voltage wires. Otherwise called the COP system.

So far, the COP system is not very widespread, but leading automakers prefer it: despite its apparent complexity, the final ignition system includes only a few elements that must work in accordance with the movement of the pistons in the cylinders. With it, drivers benefit in reliability, repair cost and, oddly enough, appearance - there is no longer sagging wiring in the engine compartment.

Let's figure out replacement time

Problems with the ignition coil largely duplicate those of spark plugs. Namely:

- Gasoline consumption has increased;

- The engine refuses to work;

- Power has dropped;

- Exhaust gases have become more “dirty”;

- The engine began to “trouble”;

- Suspicious vibration of the unit appeared;

- It became difficult to start.

At the same time, as we wrote above, the life of the coils may decrease overall a number of reasons: ingress of water, oil vapors and auto chemicals, overheating. Any coils instantly fail due to insulation breakdown. And the spark plugs themselves can put a lot of stress on them, causing the coil to burn out. Particularly vulnerable are individual systems that operate at extreme temperatures and require additional protection.

About the expensive manufacturing process

Both large transformers and windings for electric motors and small automobile coils cost a lot of money. Of course, there is no point in comparing automotive electrics with those at the station, but both are very demanding on materials and production technologies.

Since the secondary winding is made up of small wire, correct winding cannot be a simple matter: a wire 0.1 mm thick must lie flat, without the slightest distortion. If you see even a small gap in the coil, you can be sure that the entire product will begin to heat up. Along with overheating, the insulation will fail.

Extremely important pressing in wires. When the engine is running, the car begins to vibrate, which means the layout of small wiring inside the coils plays a role. If they dangle loosely, there is a risk of a short circuit.

High demands are placed on materials. The reel body must withstand even large mechanical loads. Today the body consists of impact-resistant ABS plastic. The insulating materials in modern coils can even withstand chemically aggressive environments.

We extend the life of ignition coils

Manufacturers place the coils in housings filled with epoxy resin, and most often transformer oil. This is done to prevent the device from overheating. So it is always the responsibility of the car owner to check the part for mechanical damage.

Coils depend on the quality of the wiring. High voltage wires must be kept clean. The same applies to terminals that are covered with a layer of oxide and dirt.

Do not forget watch the candles. They are changed relatively rarely, but the case of using the same spark plugs throughout the entire cycle of use of the car from purchase to disposal is quite rare - faulty spark plugs need to be changed as soon as possible, otherwise they will “kill” the coils.

Alas, the ignition coils are beyond repair. The coils in them are packed so tightly that in the event of an insulation breakdown, there is no way to help the situation. In this case, you need to change the entire device. The same applies to cases of overheating.

Making the right choice

It is best to choose the original, guided by the VIN code of the car. Since the ignition coil is located somewhere in the middle of the ignition circuit, it reacts sharply to any deviations from the characteristics specified by the vehicle manufacturer. For example, if a spark plug requires more energy than the coil can provide, the latter will simply burn out. You can get another “bonus”: if the claim The spark plug gap is very large, high voltage will try to find a workaround, that is, it will break through the insulation.

You can also go to your dealer and provide him with information about the following:

- Auto engine;

- Model;

- Year of issue;

- Vehicle body type.

It will pick up the coil even if it has been installed non-standard equipment. Or you can simply remove the coil and ask the dealer to find the same or an identical replacement.

Brand tour

A significant number of OEM reels are in fact produced by the companies that will be listed. This does not mean that there is no point in taking the original. Rather, you gain time by almost immediately selecting the spare part you need, installing it and getting back on the road.

Of the expensive goods, you should pay attention to those that are in boxes with names following companies: Valeo (France), Beru (Germany), Magneti Marelli (Italy). The quality of the coils from these companies is very high, but the price, as they say, is steep.

Coils from these companies are very popular: Bosch (Germany), NGK (Japan), Tesla (Czech Republic).

A budget solution can be reels from the Czech company Profit, as well as the well-known Danish JP Group. They will have to be replaced more often than more expensive devices, but even in this case their purchase will be profitable.

Conclusion

Knowing how to choose the right ignition coils will always be useful to you. Firstly, this device fails quite often. Many car enthusiasts confuse coil malfunctions with those of spark plugs or high-voltage wires. Secondly, understanding the specifics of making coils and their operation will help you not only recognize a fake, but also correctly select adjacent components, such as the aforementioned spark plugs and wires. Typically, ignition coils don't cost a lot of money, but if you have a new car with a custom ignition system, replacement will cost a pretty penny. In case of replacement, we recommend taking coils from Valeo, Beru (friends who are motorists will definitely recommend them to you) or, if finances are limited, products from Profit and the Danish JP Group. Do not forget also that only specialists at a service station can fully diagnose the ignition system.

An ignition coil, often called a bobbin, is a step-up electrical transformer that produces a high-voltage electrical pulse. The pulse is converted into a spark at the spark plug electrodes and ignites the combustible mixture in the cylinder. The quality of the spark and the timeliness of its formation ensures reliable engine operation.

Before purchasing a new reel, try to find out its reliability, according to reviews from its owners. Ask about the mileage that the device has withstood, whether the engine response and fuel consumption, maximum speed and CO emissions have changed.

The coil design must ensure:

- reliable insulation between windings and turns;

- high electrical resistance between the body and ground;

- strength of the case, especially plastic parts;

- absence of microcracks;

- reliability of electrical contacts and connections.

A high-quality reel can withstand temperatures up to 180°C.

Types of ignition coils

Ignition coils provide sparking for all spark plugs in turn using distributors. Switched devices include the B-116 ignition coil and its varieties:

- B-114;

- B-115;

- B-117.

Externally, the devices are similar, but have different resistances and inductances of the primary and secondary windings and are intended for use in various ignition systems. For example, B-114 is used in contact systems, and B-116 with contactless transistor distributors. Both coils will work in circuits not intended for them, but not for long.

B-114 and B-117 are similar in structure, but have different terminal designations and winding data. In some cases, their mutual replacement can give a positive result, but setting the ignition using the standard method will not work. We'll have to act on a whim.

The B-114 coil has a three times higher transformation ratio than the others. Therefore, it is advisable to use B-114 in powerful engines running on low-octane fuel, for example:

- ZIL 130, 131;

- GAZ-53, 66, 3102;

- KaVZ.

Characteristics of popular ignition coils

| Transformation ratio | Design features | Applicability of ignition coils | |

|---|---|---|---|

| B114-B | 227 | R, M, DR | ZIL-130, 131; GAZ-56, 66, 3102; PAZ, KAvZ |

| B115-V | 88 | R, M, DR | M-412, 2140, 2141; GAZ-24; ZAZ-968 and others. |

| B116 | 153 | R, M, DR | GAZ-2410, 31029 |

| B117 | 78.5 | R, M | VAZ-2101,…07, 2121 |

| B118 | 115 | R, M, E, DR | ZIL-131; GAZ-66, etc. |

| 27.3705 | 82 | R, M | VAZ-2104,...09, 2121; M-2141; ZAZ-1102 |

| 29.3705 | 90 | R, S | VAZ-2108, 09 (MSUD); VAZ-1111; VAZ-2110 |

| 3009.3705 | 70 | Z, S | GAZ-3302 (MSUD) |

| 3112.3705 | 80 | Z, S | VAZ-2107,...12; GAZ-31029 |

| 8352.12 | R, M | VAZ-2110,…12 |

Z - closed magnetic circuit;

M - oil-filled coil;

C - dry coil;

E - shielded coil;

DR - the coil has additional resistance (0.9...1.0 Ohm)

Bobbins may differ in some minor nuances that affect the smooth operation of the engine. For example, a B-115V reel can be replaced with a B-117A. The characteristics of the B-115V and B-117A are almost identical. But the spark discharge current of the B-115V is more powerful - 38 mA, while the B-117A is only 30 mA. A powerful spark is better than a weak one, and replacing the B-115V with the B-117A does not lead to any negative consequences. But owners of cars with tachometers will find that the device readings do not coincide with the actual ones. This is due to the absence of an additional resistor in the 117 model. That is, replacing almost identical B-115V devices with B-117A, or vice versa, is not always correct.

If your car has a B116 ignition coil, then you should know that they are available in two modifications. For contact and non-contact systems. Modifications 03, 04 for contactless.

In modern cars, individual coils are more often used, for each spark plug separately. Individual step-up transformers for each spark plug significantly simplify the ignition system by eliminating the distribution module from the electrical circuit

The most popular manufacturers of such devices are:

- German company Bosch;

- Taiwanese Dynatec;

- Italian

But if the first company, Bosch, can be considered the general developer of devices, then the second Dynatec and ERA produce their clones, but at a fairly high technical level and are almost as reliable as the original, despite the lower price.

The device of a classic ignition coil

All cars produced before the 1980s had a single ignition coil, which was a step-up transformer.

The main elements of the device: 1. central (high-voltage terminal), protected by a cover; 2. plastic cover; 3. secondary winding; 4. primary winding; 5. magnetic circuit; 6. iron core; 7. body.

A 12 V pulse is applied to the primary winding, which is converted into a high-voltage discharge with a voltage of 20-30 kilovolts at the electrodes of the spark plugs. High-voltage voltage pulses are supplied to the spark plugs one by one using a contact or electronic distributor.

Individual coil device

Individual bobbins are fundamentally no different from classic ones, but they are more reliable, at least because they are at least four times less likely to participate in spark formation, which greatly increases their service life.

In addition, individual reels are often equipped with a diode that cuts off high reverse voltage.

Such coils heat up much less, are reliable and are easily adjusted by the central processor to achieve optimal engine operation under different loads.

Features of replacing automotive ignition coils

For example, if the BYD F3 ignition coil for a 4G18 engine fails, then you can choose a couple of options as a replacement:

- supplied by the manufacturer - BOSCH, F01R00A010;

- similar, under serial number 880317A, manufactured by ERA.

Interestingly, Dynatec does not produce ignition devices for such engines, so don't bother looking.

Considering that, according to car service workers, the Italian ERA coil is as reliable as a Bosch ignition coil, but much cheaper, there is absolutely no point in spending extra money on the original. However, the German quality of BOSCH, even in the Chinese version, is much more convincing than the high-quality cover version of the Italian company ERA.

However, it should be noted that the BOSCH company, being a generator of original ideas, regularly modernizes its products, which cannot be said about companies like ERA that produce copies.

But even when purchasing BOSCH spare parts, carefully check the product number. Within the same series there may be slight differences in the shape of the fasteners or the thickness and diameter of the gaskets, which can complicate the installation of the device. It’s harder to make a mistake with ERA spare parts; their range of products is much more modest than that of BOSCH.

If you are the owner of a car from the Volzhsky plant, and somehow the miracle of the Soviet automobile industry, a bobbin produced by SOATE (Stary Oskol), works for you, then feel free to replace it with a Dynatec analogue. AvtoVAZ recommended such a replacement back in 2012, and did it for free at branded service stations. But it is better to replace the module with a similar one manufactured by BOSCH.

Features of choosing motorcycle ignition coils

Not only automobile internal combustion engines are equipped with step-up transformers for spark generation; they are present in:

- boat motors;

- mopeds and motorcycles;

- lawnmowers;

- chainsaws;

- electric generators.

If you are selecting an ignition coil for a Verkhovina moped, usually a B-300 was installed in it, then please note that the device with the similar name B-300B has a smaller number of turns in the field winding. Therefore, replacing the B-300 with the B-300B is impossible. Usually the engine doesn't even start. But if the B-300 is replaced with a similar device from the IZH motorcycle, the motor will work perfectly.

Soviet motor scooters such as “Ant” and “Tourist” used B-51 reels. It differs from automotive devices in that not 12, but 6 volts are supplied to the primary winding. The design of the B-51 is no different from other motorcycle reels. Many owners of scooters with B-51 coils replace them with 12-volt car ones. The transformation coefficient is enough to produce a high-quality spark, no worse than from the B-51.

Choosing a reel for a chainsaw

If you are the owner of the popular Taiwanese chainsaw Shtil: MS170, MS180, 017 or 018 and are actively working with it, then you may have already encountered the problem of magneto failure. The Stihl company equips these chainsaws with the same CH000013-5 coils. Shtil 180 coils have proven to be quite reliable devices, so you should not replace Shtil 180 with an analogue, except in extreme cases. Practice has shown that analogues of reels from 180 unknown manufacturers do not last even two working weeks. At the same time, the original models last for more than one year, even under heavy load. Also, 180 coils serve well on other Chinese chainsaws.

When purchasing an ignition coil, you should first of all pay attention to its characteristics, take into account the impact of their discrepancy on engine operation and choose a product from well-known brands. If you choose an analogue, then be prepared for the fact that you will have to rebuild some parameters of the ignition system.

The ignition system coil is a very important element, the main task of which is to convert voltage from low voltage to high voltage. This voltage comes directly from the battery or generator. The coil of a contact ignition system is quite different from a similar element in a contactless system.

Contact ignition coil

In a contact ignition system, the coil consists of several important elements: a core, primary and secondary windings, a cardboard tube, a breaker and an additional resistor. A feature of the primary winding compared to the secondary is a smaller number of turns of copper wire (up to 400). In the secondary winding of the coil, their number can reach 25 thousand, but their diameter is several times smaller. All copper wires in the ignition coil are well insulated. The coil core reduces the formation of eddy currents; it consists of strips of transformer steel, which are also well insulated from each other. The lower part of the core is installed in a special porcelain insulator. Now there is no need to list the principle of operation of the coil in detail; it is enough to just mention that in a contact system such an element (voltage converter) is of key importance.

Contactless ignition coil

In a contactless ignition system, the coil performs exactly the same functions. And the difference manifests itself only in the direct structure of the element that converts voltage. It is also worth noting that the electronic switch interrupts the power supply circuit of the primary coil. As for the ignition system itself, the non-contact one is much better in many respects: the ability to start and operate the engine at low temperatures, there is no disturbance in the uniformity of spark distribution in the cylinders, and there is no vibration. All these advantages are provided by the coil itself in a contactless ignition system.

Coil comparison

When it comes to the differences between a coil of a contact ignition system and a contactless one, everyone immediately pays attention to the markings. Indeed, from it you can immediately find out for which system the coil is used. However, we are interested in the external and technical differences of the coils, so we will present the differences in these parameters:

- The coil in the contact ignition system has a larger number of turns in the primary winding. This change directly affects the resistance and the amount of current passing. In addition, limiting the current on the contacts is related to safety (so that the contacts do not burn).

- The coil breaker contacts in a contactless ignition system do not become dirty or burn. This reliability allows for one important advantage: setting the ignition timing does not take much time.

- The coil in a contactless ignition system is more powerful and reliable. This advantage is directly related to the fact that the most contactless ignition system is a more reliable option. Therefore, in such a system, the coil provides greater engine power.

Conclusions website

- They have different markings to indicate the difference between the two coils.

- In a contact system, the coil has a larger number of turns.

- The coil breaker contacts of the non-contact system are more reliable.

- The coil itself in a contactless ignition system produces more power.